What is a Furnace? Everything You Need to Know.

We're all familiar with the comforting sound of a home furnace warming up; that gentle lull that comes up from the registers, carrying with it the promise of cozy warmth on a cold winter’s night.

To provide indoor heating, a furnace warms the air, which is then blown out and distributed via ductwork around the home. A house furnace is the central component of a forced air heating system, as opposed to a hydronic heating system, in which a boiler heats a home with water.

This guide provides the basics of home furnace operation and what you need to know when shopping for a new one. If you haven’t read our Homeowner’s Guide to HVAC, it might be a good intro for you to get a general idea of how heating, cooling, and ventilation work in your home.

A Brief History of Furnaces

The earliest furnaces used either wood or coal to heat air, which rose via natural convection or gravity to heat living spaces. During the late 19th and early 20th century, they were called octopus furnaces because they had many "arms" of venting going in all directions to adequately heat the home.

One of the major headaches associated with these types of furnaces was their regular need for fresh fuel. During the winter, people would have to add wood or coal to the combustion chamber four or five times per day.

One of the major headaches associated with these types of furnaces was their regular need for fresh fuel. During the winter, people would have to add wood or coal to the combustion chamber four or five times per day.

To stay warm in the morning, you would probably have had to wake up in the middle of the night to add fuel. Not to mention, this form of heating was very inefficient, and you risked setting your house on fire, as well as carbon monoxide poisoning.

In the late nineteenth and early twentieth centuries, the invention of electricity and the bunsen burner paved the way for the modern natural gas furnace system. Now it was possible to create an automatic, controlled flame that could transfer adequate heat around the home.

By the 1930s in the United States, manually adding fuel to a furnace was becoming a thing of the past. The modern furnace was born. Today, it is one of the most common home heating options.

How Does a Gas Furnace Work?

A gas furnace works as follows:

- A thermostat signals the furnace’s circuit board when the home falls below set temperature.

- The gas burner ignites, which combines fresh air, fuel and spark to create controlled flames.

- The flames heat a metal heat exchanger, which transfers the heat to passing air and contains combustion fumes.

- A blower forces the warm air through ductwork around the home.

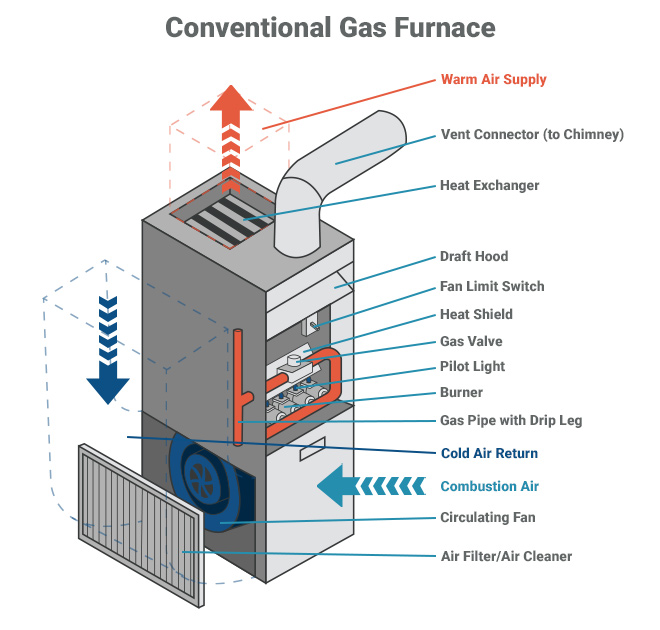

Gas Furnace Components

The basic parts of a furnace system involve the thermostat, burners, draft inducer, heat exchanger, and blower.

Thermostat

When you set your thermostat, it monitors when the indoor temperature falls below the setpoint. Once it does, the thermostat tells the furnace’s circuit board that it’s time to start heating.

Draft Inducer

The draft inducer draws in fresh air into the furnace to provide a steady flow of oxygen for the burners. This oxygen is crucial to the combustion process and to maintaining overall energy efficiency.

Another important job of the draft inducer is to blow out any remaining exhaust gases lingering around the heat exchanger. This helps prevent any accidental combustion, as well as harmful exhaust from back drafting into the home.

Burners

The gas burners get their marching orders from the thermostat. Once the signal comes to heat the home, an electric charge (or pilot light on older models) ignites the flame. The combustion is created by the mixture of fresh oxygen (sent by the draft inducer) and fuel (natural gas, propane or oil).

The gas burners get their marching orders from the thermostat. Once the signal comes to heat the home, an electric charge (or pilot light on older models) ignites the flame. The combustion is created by the mixture of fresh oxygen (sent by the draft inducer) and fuel (natural gas, propane or oil).

There are three main types of furnace burners:

- Single-stage burners provide one maximum level of flame output regardless of conditions. This creates inefficiency when the temperature is mild because the flame is still running at high output.

- Two-stage burners have low-fire and high-fire output flames. High-fire mode uses the maximum flame output while low-fire mode runs at 40%-60% of the rated capacity. This helps increase efficiency and home comfort in milder weather when you don’t want or need maximum power.

- Modulating burners can operate a flame anywhere between a minimum and maximum heating capacity, leading to high efficiency. They adapt to home temperature needs, adjusting the flame to use the minimum amount of energy necessary for effective heating.

Heat Exchanger

A heat exchanger is nothing more than a series of metal tubes that are heated by the burner. Once hot, the heat exchanger can transfer that heat to air coming in from the return ducts.

It also prevents deadly exhaust gases from moving into the air stream. Some high-efficiency heat exchangers are curved to maximize heat transfer.

Blower

The blower fan pushes return air from the home past the heat exchangers, warming it. This warm air is then forced around the home through ductwork. There are two main types of furnace blowers.

- Multi-speed blowers can be set to different speeds (low, medium, high). They are set at the time of installation, depending on the load calculation and required CFM, and are committed to blowing at that speed regardless of changing conditions (ie. clogged filter, closed register, etc.)

- Variable Speed blowers are more efficient because they can adjust their speed based on flow rates, temperatures, and other information.

Furnace Orientation

Furnace orientation refers to how the system is positioned for air to enter and leave. Depending on the location of the installation, a furnace can take on one of three common orientations: upflow, downflow, horizontal and lowboy.

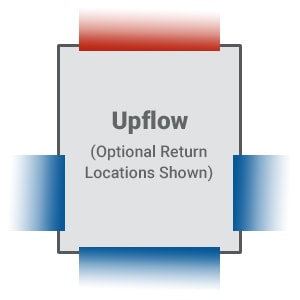

Upflow Furnace

In an upflow furnace, return air (air entering the furnace to be heated) enters from either the bottom or sides of the unit, is heated, and exits from the top (supply air). This is ideal for basement or closet applications where the ductwork is above the unit.

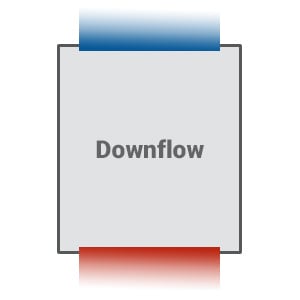

Downflow Furnace

Return air enters from the top of a downflow furnace. The heated supply air then exits out the bottom of the unit. Downflow models are best for applications where the ductwork is below the furnace, typically in a crawlspace and in certain commercial applications.

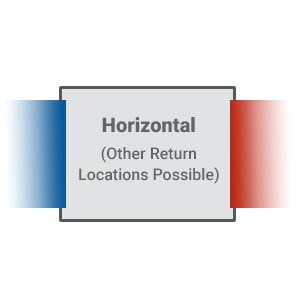

Horizontal Furnace

A horizontal furnace is best for applications with limited height like attics and crawlspaces. Return air enters through one side and exits through the other side of the horizontal unit.

Lowboy Furnace

In lowboy furnaces, air both enters and exits through the top of the unit. Once common in older homes, lowboy furnaces are becoming a thing of the past. Why? Newer applications will typically choose one of the other orientations, especially the upflow option, instead of a low boy.

Furnace Efficiency

The efficiency of a furnace is measured by its Annual Fuel Utilization Efficiency (AFUE), which indicates the percentage of fuel that is converted into heat energy.

For example, a furnace AFUE rating of 80% (the federal minimum) means the unit can use 80% of its heat energy to keep you warm. The remaining 20% of heat energy is lost due to venting of the exhaust.

For example, a furnace AFUE rating of 80% (the federal minimum) means the unit can use 80% of its heat energy to keep you warm. The remaining 20% of heat energy is lost due to venting of the exhaust.

It's like for every dollar of heat - you are wasting 20 cents.

Typically, high-efficiency furnaces use condensing technology and have an AFUE of 90% or higher. While lower efficiency furnaces use one heat exchanger, a condensing furnace uses a second one that captures heat from the exhaust gases. This extra heat is then repurposed to heat the home.

Other factors that impact furnace efficiency include:

Burner Efficiency

As discussed above, a modulating burner can adjust the flame output based on how much heat your home actually needs, which cuts down on waste.

Blower Motor

If your blower uses a highly-efficient electronically commutated motor (ECM), it can adjust speed based on demand and save electricity. ECM motors are common in variable speed blowers.

The less efficient but more affordable option is a permanent split capacitor (PSC) motor, which cannot adjust to changing conditions and is used with multi-speed blowers.

In between are constant torque motors which have the efficiency of ECM motors but lack the responsiveness. Still, they are more affordable than ECM motors and a step above PSC motors.

Furnace Filters

The primary job of a furnace filter is to prevent harmful return air particles from entering and damaging your furnace. Naturally, when the filters get clogged with debris, they force the blower motor to work harder to keep air moving. This results in lower efficiency because more electricity is being used.

The primary job of a furnace filter is to prevent harmful return air particles from entering and damaging your furnace. Naturally, when the filters get clogged with debris, they force the blower motor to work harder to keep air moving. This results in lower efficiency because more electricity is being used.

That's why you should change your furnace filter every 1-3 months, or even more if you have multiple pets or allergies.

Home Environment

The "envelope," or airtightness in a home, can impact how much heat is lost--and how hard your furnace needs to work to maintain a comfortable temperature. Poor insulation and air leaks are just a couple of factors that could impact your home's envelope.

Furnace Venting

To get rid of exhaust, furnaces typically use either chimney or direct venting.

Chimney vents, as the name implies, discharge exhaust gases from the heat exchanger out the chimney via natural convection. The hot exhaust rises through large vent connections to exit the home. This venting style is found only on furnaces with a low AFUE rating of 80%. Fresh air is pulled in from the surrounding space. Roughly 80% of chimney vent furnaces use a metal exhaust pipe.

Direct vent furnaces exhaust either vertically through a ceiling or horizontally through a side wall. They use built-in motors to blow the exhaust out one pipe and bring in fresh air from outside through a second pipe. Normally, PVC piping can be used for venting because the units' efficiency translates to cooler exhaust temperatures.

Armed with this basic understanding of furnaces, you will be able to shop intelligently when it's the middle of winter and your old one has given out.