{"storeInfo":{"id":13,"name":"Power Equipment Direct","domain":"powerequipmentdirect.com","initials":"PED","url":"https:\/\/www.powerequipmentdirect.com","path":"\/var\/www\/vhosts\/ped.com\/"},"headerNavJSON":"{\"MainLinks\":[{\"URL\":\"\\\/outdoor\\\/air-compressors-direct.html\",\"displayText\":\"Air Compressors\",\"sectionLinks\":{\"columns\":\"6\",\"linkItems\":[{\"URL\":\"\\\/tools\\\/portable-air-compressors.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/compressor-13-1.jpg\",\"displayText\":\"Portable\"},{\"URL\":\"\\\/tools\\\/gas-air-compressors.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/compressor-13-2.jpg\",\"displayText\":\"Gas\"},{\"URL\":\"\\\/tools\\\/single-stage-air-compressors.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/compressor-13-3.jpg\",\"displayText\":\"Single-Stage\"},{\"URL\":\"\\\/tools\\\/two-stage-air-compressors.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/compressor-13-4.jpg\",\"displayText\":\"Two-Stage\"},{\"URL\":\"\\\/tools\\\/rotary-screw-air-compressors.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/compressor-13-5.jpg\",\"displayText\":\"Rotary Screw\"},{\"URL\":\"\\\/tools\\\/scroll-compressors.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/compressor-13-6.jpg\",\"displayText\":\"Scroll\"}]},\"subCategories\":[{\"URL\":null,\"type\":\"list\",\"title\":\"Featured Categories\",\"linkItems\":[{\"URL\":\"\\\/tools\\\/wheelbarrow-air-compressors.html\",\"displayText\":\"Wheelbarrow\"},{\"URL\":\"\\\/tools\\\/air-dryers.html\",\"displayText\":\"Air Dryers\"},{\"URL\":\"\\\/tools\\\/truck-mount-air-compressors.html\",\"displayText\":\"Truck Mount\"},{\"URL\":\"\\\/tools\\\/twin-stack-air-compressors.html\",\"displayText\":\"Twin Stack\"},{\"URL\":\"\\\/oil-free-air-compressors.html\",\"displayText\":\"Oil Free\"}]},{\"URL\":null,\"type\":\"list\",\"title\":\"Accessories\",\"linkItems\":[{\"URL\":\"\\\/tools\\\/impact-wrenches-pneumatic.html\",\"displayText\":\"Impact Wrenches\"},{\"URL\":\"\\\/tools\\\/air-treatment.html\",\"displayText\":\"Air Treatment\"},{\"URL\":\"\\\/tools\\\/air-tools.html\",\"displayText\":\"Air Tools\"},{\"URL\":\"\\\/tools\\\/air-compressor-accessories.html\",\"displayText\":\"All Accessories\"},{\"URL\":\"\\\/tools\\\/line-filters.html\",\"displayText\":\"Line Filters\"}]},{\"URL\":null,\"type\":\"list\",\"title\":\"Shop by Brand\",\"linkItems\":[{\"URL\":\"\\\/tools\\\/ingersoll-rand-air-compressors.html\",\"displayText\":\"Ingersoll Rand\"},{\"URL\":\"\\\/tools\\\/quincy-air-compressors.html\",\"displayText\":\"Quincy\"},{\"URL\":\"\\\/tools\\\/atlas-copco-compressors.html\",\"displayText\":\"Atlas Copco\"},{\"URL\":\"\\\/tools\\\/emax-air-compressors.html\",\"displayText\":\"EMAX\"},{\"URL\":\"\\\/tools\\\/industrial-air-compressors.html\",\"displayText\":\"Industrial Air\"}]},{\"URL\":\"\\\/stories\\\/156-How-to-Pick-the-Perfect-Air-Compressor.html\",\"type\":\"image\",\"title\":\"Buyer's Guide\",\"imageURL\":\"\\\/nav-article-image\\\/305\\\/social_img_156.jpg\",\"linkItems\":[],\"displayText\":\"The Ultimate Air Compressor Guide\"}]},{\"URL\":\"\\\/outdoor\\\/electric-generators-direct.html\",\"displayText\":\"Electric Generators\",\"sectionLinks\":{\"columns\":\"6\",\"linkItems\":[{\"URL\":\"\\\/power\\\/portable-generators.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/generator-13-1.jpg\",\"displayText\":\"Portable\"},{\"URL\":\"\\\/power\\\/home-standby-generators.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/generator-13-2.jpg\",\"displayText\":\"Home Standby\"},{\"URL\":\"\\\/power\\\/commercial-standby-generators.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/generator-13-3.jpg\",\"displayText\":\"Commercial\"},{\"URL\":\"\\\/power\\\/rv-generators.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/generator-13-4.jpg\",\"displayText\":\"RV\"},{\"URL\":\"\\\/power\\\/pto-generators.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/generator-13-5.jpg\",\"displayText\":\"PTO\"},{\"URL\":\"\\\/power\\\/transfer-switches.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/generator-13-6.jpg\",\"displayText\":\"Transfer Switches\"}]},\"subCategories\":[{\"URL\":null,\"type\":\"list\",\"title\":\"Featured Categories\",\"linkItems\":[{\"URL\":\"\\\/power\\\/whole-house-standby-generators.html\",\"displayText\":\"Whole House\"},{\"URL\":\"\\\/power\\\/inverter-generators.html\",\"displayText\":\"Inverter\"},{\"URL\":\"\\\/power\\\/electric-start-portable-generators.html\",\"displayText\":\"Electric Start\"},{\"URL\":\"\\\/power\\\/dual-fuel-generators.html\",\"displayText\":\"Dual Fuel\"},{\"URL\":\"\\\/power\\\/solar-generators.html\",\"displayText\":\"Solar Powered\"}]},{\"URL\":null,\"type\":\"list\",\"title\":\"Accessories\",\"linkItems\":[{\"URL\":\"\\\/power\\\/generator-power-cords.html\",\"displayText\":\"Power Cords\"},{\"URL\":\"\\\/power\\\/power-inlet-boxes.html\",\"displayText\":\"Power Inlet Boxes\"},{\"URL\":\"\\\/power\\\/generator-maintenance-kits.html\",\"displayText\":\"Maintenance Kits\"},{\"URL\":\"\\\/power\\\/portable-generator-covers.html\",\"displayText\":\"Covers & Tents\"},{\"URL\":\"\\\/outdoor\\\/electric-generator-accessories.html\",\"displayText\":\"All Accessories\"}]},{\"URL\":null,\"type\":\"list\",\"title\":\"Shop by Brand\",\"linkItems\":[{\"URL\":\"\\\/outdoor\\\/generac.html\",\"displayText\":\"Generac\"},{\"URL\":\"\\\/power\\\/honda-generators.html\",\"displayText\":\"Honda\"},{\"URL\":\"\\\/power\\\/kohler-generators.html\",\"displayText\":\"Kohler\"},{\"URL\":\"\\\/power\\\/briggs-and-stratton-generators.html\",\"displayText\":\"Briggs & Stratton\"},{\"URL\":\"\\\/power\\\/champion-generators.html\",\"displayText\":\"Champion\"}]},{\"URL\":\"\\\/stories\\\/305-How-to-Pick-the-Perfect-Electric-Generator.html\",\"type\":\"image\",\"title\":\"Buyer's Guide\",\"imageURL\":\"\\\/nav-article-image\\\/305\\\/social_img_305.jpg\",\"linkItems\":[],\"displayText\":\"What Kind of Generator do I Need for my House\"}]},{\"URL\":\"\\\/outdoor\\\/pressure-washers-direct.html\",\"displayText\":\"Pressure Washers\",\"sectionLinks\":{\"columns\":\"6\",\"linkItems\":[{\"URL\":\"\\\/power\\\/gas-pressure-washers.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/pressure-washer-13-1.jpg\",\"displayText\":\"Gas\"},{\"URL\":\"\\\/power\\\/electric-pressure-washers.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/pressure-washer-13-2.jpg\",\"displayText\":\"Electric\"},{\"URL\":\"\\\/power\\\/pressure-washer-pumps.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/pressure-washer-13-3.jpg\",\"displayText\":\"Pumps\"},{\"URL\":\"\\\/power\\\/pressure-washer-hoses.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/pressure-washer-13-4.jpg\",\"displayText\":\"Hoses\"},{\"URL\":\"\\\/power\\\/jetters.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/pressure-washer-13-5.jpg\",\"displayText\":\"Jetters\"},{\"URL\":\"\\\/power\\\/commercial-pressure-washers.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/pressure-washer-13-6.jpg\",\"displayText\":\"Commercial\"}]},\"subCategories\":[{\"URL\":null,\"type\":\"list\",\"title\":\"Featured Categories\",\"linkItems\":[{\"URL\":\"\\\/power\\\/commercial-start-your-own-business-kits.html\",\"displayText\":\"Business Kits\"},{\"URL\":\"\\\/power\\\/commercial-truck-mount-pressure-washers.html\",\"displayText\":\"Truck Mount\"},{\"URL\":\"\\\/power\\\/commercial-wall-mount-pressure-washers.html\",\"displayText\":\"Wall Mount\"},{\"URL\":\"\\\/power\\\/hot-water-pressure-washers.html\",\"displayText\":\"Hot Water\"},{\"URL\":\"\\\/power\\\/gas-pressure-washers.html\",\"displayText\":\"Gas Powered\"}]},{\"URL\":null,\"type\":\"list\",\"title\":\"Accessories\",\"linkItems\":[{\"URL\":\"\\\/power\\\/surface-cleaners.html\",\"displayText\":\"Surface Cleaners\"},{\"URL\":\"\\\/power\\\/pressure-washer-telescoping-wands.html\",\"displayText\":\"Telescoping Wands\"},{\"URL\":\"\\\/power\\\/pressure-washer-spray-rollers.html\",\"displayText\":\"Spray Guns\"},{\"URL\":\"\\\/power\\\/pressure-washer-soap-nozzles.html\",\"displayText\":\"Nozzles\"},{\"URL\":\"\\\/power\\\/pressure-washer-attachment.html\",\"displayText\":\"All Accessories\"}]},{\"URL\":null,\"type\":\"list\",\"title\":\"Shop by Brand\",\"linkItems\":[{\"URL\":\"\\\/power\\\/simpson-pressure-washers.html\",\"displayText\":\"Simpson\"},{\"URL\":\"\\\/power\\\/pressure-pro-pressure-washers.html\",\"displayText\":\"Pressure-Pro\"},{\"URL\":\"\\\/power\\\/be-pressure-washers.html\",\"displayText\":\"BE\"},{\"URL\":\"\\\/power\\\/general-pump-pressure-washers.html\",\"displayText\":\"General Pump\"},{\"URL\":\"\\\/power\\\/easy-kleen-pressure-washers.html\",\"displayText\":\"Easy-Kleen\"}]},{\"URL\":\"\\\/stories\\\/343-How-to-Pick-the-Perfect-Pressure-Washer.html\",\"type\":\"image\",\"title\":\"Buyer's Guide\",\"imageURL\":\"\\\/nav-article-image\\\/305\\\/social_img_343.jpg\",\"linkItems\":[],\"displayText\":\"Pressure Washer Buyer's Guide\"}]},{\"URL\":\"\\\/outdoor\\\/sump-pumps-direct.html\",\"displayText\":\"Sump Pumps\",\"sectionLinks\":{\"columns\":\"6\",\"linkItems\":[{\"URL\":\"\\\/pumps\\\/primary-sump-pumps.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/primary_56776234fd355c5a6971fc4fe3b1a559.jpg\",\"displayText\":\"Primary\"},{\"URL\":\"\\\/pumps\\\/combination-sump-pump-systems.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/Combination_d1accf365a102db5033f2a6f6bd37f98.jpg\",\"displayText\":\"Combination\"},{\"URL\":\"\\\/pumps\\\/battery-backup-sump-pumps.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/Battery Backup_57ed4885b879f30ee0134fc50cf51b8f.jpg\",\"displayText\":\"Battery Backup\"},{\"URL\":\"\\\/pumps\\\/sewage-pumps.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/Sewage_7c435fa06b22cee7de46cb44ef798ee7.jpg\",\"displayText\":\"Sewage\"},{\"URL\":\"\\\/pumps\\\/grinder-pumps.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/Grinder_74abf9c1c797dbdc6bdaedc569127969.jpg\",\"displayText\":\"Grinder\"},{\"URL\":\"\\\/pumps\\\/specialty-sump-pumps.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/Specialty_2e682b88db34300c4023504e9e23c845.jpg\",\"displayText\":\"Specialty\"}]},\"subCategories\":[{\"URL\":null,\"type\":\"list\",\"title\":\"Featured Categories\",\"linkItems\":[{\"URL\":\"\\\/pumps\\\/primary-submersible-sump-pumps.html\",\"displayText\":\"Primary Submersible\"},{\"URL\":\"\\\/pumps\\\/sewage-pump-systems.html\",\"displayText\":\"Sewage Systems\"},{\"URL\":\"\\\/pumps\\\/effluent-pumps.html\",\"displayText\":\"Effluent\"},{\"URL\":\"\\\/pumps\\\/laundry-drain-pump-systems.html\",\"displayText\":\"Drain\"},{\"URL\":\"\\\/pumps\\\/primary-pedestal-sump-pumps.html\",\"displayText\":\"Primary Pedestal\"}]},{\"URL\":null,\"type\":\"list\",\"title\":\"Accessories\",\"linkItems\":[{\"URL\":\"\\\/pumps\\\/sump-pump-batteries.html\",\"displayText\":\"Batteries\"},{\"URL\":\"\\\/pumps\\\/sump-pump-switches.html\",\"displayText\":\"Switches\"},{\"URL\":\"\\\/pumps\\\/sump-pump-and-sewage-pump-control-boxes.html\",\"displayText\":\"Control Boxes\"},{\"URL\":\"\\\/pumps\\\/auxiliary-power-systems.html\",\"displayText\":\"Auxiliary Power System\"},{\"URL\":\"\\\/pumps\\\/sump-pump-accessory.html\",\"displayText\":\"All Accessories\"}]},{\"URL\":null,\"type\":\"list\",\"title\":\"Shop by Brand\",\"linkItems\":[{\"URL\":\"\\\/pumps\\\/liberty-pumps.html\",\"displayText\":\"Liberty Pumps\"},{\"URL\":\"\\\/pumps\\\/zoeller-pumps.html\",\"displayText\":\"Zoeller\"},{\"URL\":\"\\\/pumps\\\/phcc-pro-series-pumps.html\",\"displayText\":\"Pro Series\"},{\"URL\":\"\\\/pumps\\\/bur-cam-pumps.html\",\"displayText\":\"Burcam\"},{\"URL\":\"\\\/pumps\\\/ion-pumps.html\",\"displayText\":\"iON Products\"}]},{\"URL\":\"\\\/stories\\\/784-Best-Selling-and-Top-Rated-Sump-Pumps.html\",\"type\":\"image\",\"title\":\"Buyer's Guide\",\"imageURL\":\"\\\/nav-article-image\\\/305\\\/social_img_784.jpg\",\"linkItems\":[],\"displayText\":\"The Best Sump Pumps of 2024\"}]},{\"URL\":\"\\\/outdoor\\\/water-pumps-direct.html\",\"displayText\":\"Water Pumps\",\"sectionLinks\":{\"columns\":\"6\",\"linkItems\":[{\"URL\":\"\\\/pumps\\\/electric-water-pumps.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/water-pump-13-1.jpg\",\"displayText\":\"Electric\"},{\"URL\":\"\\\/pumps\\\/gas-powered-water-pumps.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/water-pump-13-2.jpg\",\"displayText\":\"Gas\"},{\"URL\":\"\\\/pumps\\\/well-pumps.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/water-pump-13-3.jpg\",\"displayText\":\"Well\"},{\"URL\":\"\\\/pumps\\\/dewatering-pumps.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/water-pump-13-5.jpg\",\"displayText\":\"Dewatering\"},{\"URL\":\"\\\/pumps\\\/trash-pumps.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/water-pump-13-6.jpg\",\"displayText\":\"Trash\"},{\"URL\":\"\\\/pumps\\\/sprinkler-pumps.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/sprinkler_503ba4a09158d65372eb111aeb27c0b3.jpg\",\"displayText\":\"Sprinkler\"}]},\"subCategories\":[{\"URL\":null,\"type\":\"list\",\"title\":\"Featured Categories\",\"linkItems\":[{\"URL\":\"\\\/pumps\\\/utility-pumps.html\",\"displayText\":\"Utility\"},{\"URL\":\"\\\/pumps\\\/chemical-pumps.html\",\"displayText\":\"Chemical\"},{\"URL\":\"\\\/pumps\\\/transfer-pumps.html\",\"displayText\":\"Transfer\"},{\"URL\":\"\\\/pumps\\\/diesel-powered-pumps.html\",\"displayText\":\"Diesel\"},{\"URL\":\"\\\/pumps\\\/miscellaneous-power-types.html\",\"displayText\":\"Specialty Power\"}]},{\"URL\":null,\"type\":\"list\",\"title\":\"Accessories\",\"linkItems\":[{\"URL\":\"\\\/pumps\\\/water-pump-discharge-hoses.html\",\"displayText\":\"Hoses\"},{\"URL\":\"\\\/pumps\\\/well-pump-control-boxes.html\",\"displayText\":\"Control Boxes\"},{\"URL\":\"\\\/pumps\\\/float-switches.html\",\"displayText\":\"Switches\"},{\"URL\":\"\\\/pumps\\\/water-pump-quick-couplings.html\",\"displayText\":\"Quick Couplings\"},{\"URL\":\"\\\/pumps\\\/water-pump-accessory.html\",\"displayText\":\"All Accessories\"}]},{\"URL\":null,\"type\":\"list\",\"title\":\"Shop by Brand\",\"linkItems\":[{\"URL\":\"\\\/pumps\\\/honda-water-pumps.html\",\"displayText\":\"Honda\"},{\"URL\":\"\\\/pumps\\\/flotec-water-pumps.html\",\"displayText\":\"Flotec\"},{\"URL\":\"\\\/pumps\\\/multiquip-water-pumps.html\",\"displayText\":\"Multiquip\"},{\"URL\":\"\\\/pumps\\\/tsurumi-water-pumps.html\",\"displayText\":\"Tsurumi Pump\"},{\"URL\":\"\\\/pumps\\\/red-lion-water-pumps.html\",\"displayText\":\"Red Lion\"}]},{\"URL\":\"\\\/stories\\\/281-How-to-Pick-the-Perfect-Water-Pump.html\",\"type\":\"image\",\"title\":\"Buyer's Guide\",\"imageURL\":\"\\\/nav-article-image\\\/305\\\/social_img_281.jpg\",\"linkItems\":[],\"displayText\":\"Water Pump Buyer's Guide\"}]},{\"URL\":null,\"displayText\":\"More\",\"sectionLinks\":{\"columns\":\"6\",\"linkItems\":[{\"URL\":\"https:\\\/\\\/www.ecomfort.com\\\/cooling\\\/ductless-mini-split-systems.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/ls120hev2_99293_600_566a8b8447567d17e07268f4f6d958a4.jpg\",\"displayText\":\"Mini Splits\"},{\"URL\":\"https:\\\/\\\/www.ecomfort.com\\\/cooling\\\/room-air-conditioners.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/mass_140040_cd360daf61cd951f5221c80ff4941449.png\",\"displayText\":\"Room ACs and PTACs\"},{\"URL\":\"\\\/power\\\/jetters.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/JD4040HG_12827_600_72dcd6c01efe128e37c54c597bd42b59.jpg\",\"displayText\":\"Jetters\"},{\"URL\":\"\\\/outdoor\\\/paint-sprayers-direct.html\",\"imageURL\":\"\\\/nav-image\\\/100\\\/805-000_76239_1000_21900ab5e97ce4d1a242111121a10762_59ff9bc3ee387c5dd0131fb6cb89b426.jpg\",\"displayText\":\"Paint Sprayers\"}]},\"subCategories\":[{\"URL\":null,\"type\":\"list\",\"title\":\"Home Equipment\",\"linkItems\":[{\"URL\":\"https:\\\/\\\/www.ecomfort.com\\\/cooling\\\/central-air-conditioners.html\",\"displayText\":\"Air Conditioners\"},{\"URL\":\"https:\\\/\\\/www.ecomfort.com\\\/heating\\\/boilers.html\",\"displayText\":\"Boilers\"},{\"URL\":\"https:\\\/\\\/www.ecomfort.com\\\/heating\\\/furnaces.html\",\"displayText\":\"Furnaces\"},{\"URL\":\"https:\\\/\\\/www.ecomfort.com\\\/cooling\\\/ductless-mini-split-systems.html\",\"displayText\":\"Mini Splits\"},{\"URL\":\"https:\\\/\\\/www.ecomfort.com\\\/water-heaters\\\/water-heaters.html\",\"displayText\":\"Water Heaters\"}]},{\"URL\":null,\"type\":\"list\",\"title\":\"Home Appliances\",\"linkItems\":[{\"URL\":\"https:\\\/\\\/www.ecomfort.com\\\/cooling\\\/beverage-coolers.html\",\"displayText\":\"Beverage Coolers\"},{\"URL\":\"https:\\\/\\\/www.ecomfort.com\\\/appliances\\\/garbage-disposals.html\",\"displayText\":\"Garbage Disposals\"},{\"URL\":\"https:\\\/\\\/www.ecomfort.com\\\/cooling\\\/kegerators.html\",\"displayText\":\"Kegerators\"},{\"URL\":\"https:\\\/\\\/www.ecomfort.com\\\/cooling\\\/room-air-conditioners.html\",\"displayText\":\"Room Air Conditioners\"},{\"URL\":\"https:\\\/\\\/www.ecomfort.com\\\/cooling\\\/wine-coolers.html\",\"displayText\":\"Wine Coolers\"}]},{\"URL\":null,\"type\":\"list\",\"title\":\"Tools\",\"linkItems\":[{\"URL\":\"\\\/tools\\\/air-tools.html\",\"displayText\":\"Air Tools\"},{\"URL\":\"https:\\\/\\\/www.ecomfort.com\\\/cooling\\\/tools.html\",\"displayText\":\"HVAC Tools\"},{\"URL\":\"\\\/outdoor\\\/paint-sprayers-direct.html\",\"displayText\":\"Paint Sprayers\"}]},{\"URL\":null,\"type\":\"list\",\"title\":\"Commercial Equipment\",\"linkItems\":[{\"URL\":\"\\\/tools\\\/demolition-tools.html\",\"displayText\":\"Demolition Tools\"},{\"URL\":\"\\\/power\\\/jetters.html\",\"displayText\":\"Jetters\"},{\"URL\":\"\\\/power\\\/light-towers.html\",\"displayText\":\"Light Towers\"}]}]},{\"URL\":\"\\\/how-to-library.php\",\"displayText\":\"How-to-Library\",\"sectionLinks\":{\"columns\":\"6\",\"linkItems\":[{\"URL\":null,\"imageURL\":null,\"displayText\":\"\"}]},\"subCategories\":[]},{\"URL\":\"\\\/outdoor\\\/power-equipment-on-sale.html\",\"displayText\":\"Weekly Specials\",\"sectionLinks\":{\"columns\":\"6\",\"linkItems\":[{\"URL\":null,\"imageURL\":null,\"displayText\":\"\"}]},\"subCategories\":[]},{\"URL\":\"https:\\\/\\\/www.ecomfort.com\\\/\",\"displayText\":\"HVAC at eComfort.com\",\"sectionLinks\":{\"columns\":\"6\",\"linkItems\":[{\"URL\":null,\"imageURL\":null,\"displayText\":\"\"}]},\"subCategories\":[]}],\"USP\":[{\"id\":\"479\",\"URL\":\"\\\/stories\\\/479-How-To-Get-Free-Shipping-On-Power-Equipment.html\",\"className\":\"icon-nav-usp-shipping\",\"displayText\":\"Free Shipping\"},{\"id\":\"359\",\"URL\":\"\\\/stories\\\/359-Serious-Power-Equipment-Worth-Bragging-About.html\",\"className\":\"icon-nav-usp-reviews\",\"displayText\":\"Expert Recommendations\"},{\"id\":\"1261\",\"URL\":\"\\\/stories\\\/1261-Power-Equipment-Direct-Credit-Made-Simple.html\",\"className\":\"icon-nav-usp-financing\",\"displayText\":\"Financing\"},{\"id\":\"1991\",\"URL\":\"\\\/stories\\\/1991-New-Customer-Referral-Program.html\",\"className\":\"icon-referral\",\"displayText\":\"Customer Referral Program\"}]}","siteLinkJSON":"{\"Resources\":{\"How to Library\":{\"href\":\"how-to-library.php\",\"title\":\"Power Equipment Direct How-To Library\"},\"Product Reviews\":{\"href\":\"reviews.php\",\"title\":\"Customer Reviews on Power Equipment Direct Products\"},\"Recommendations\":{\"href\":\"stories\\\/359-Serious-Power-Equipment-Worth-Bragging-About.html\",\"title\":\"Product Recommendations\"},\"Weekly Specials\":{\"href\":\"outdoor\\\/power-equipment-on-sale.html\",\"title\":\"Weekly Power Equipment Direct Specials\"},\"Manuals\":{\"href\":\"stories\\\/399-How-to-Access-Old-Power-Equipment-Manuals.html\",\"title\":\"Manual Lookup\"},\"Service Centers\":{\"href\":\"stories\\\/414-How-to-Find-a-Service-Center-For-Your-Power-Equipment.html\",\"title\":\"Service Centers\"},\"Technical Support\":{\"href\":\"stories\\\/425-How-to-Find-Tech-Support-For-Your-Power-Equipment.html\",\"title\":\"Technical Support\"}},\"Account\":{\"My Account\":{\"href\":\"account.php\",\"title\":\"Login to My Account\"},\"Email Preferences\":{\"href\":\"https:\\\/\\\/www.powerequipmentdirect.com\\\/newsletter_removal.php\",\"title\":\"Email Preferences\"},\"Manufacturer Login\":{\"href\":\"https:\\\/\\\/www.powerequipmentdirect.com\\\/partnerships\\\/login.php\",\"title\":\"Manufacturer Login\"}},\"Customer Service\":{\"Help Center\":{\"href\":\"contact_us.php\",\"title\":\"Help Center\"},\"Return Policy\":{\"href\":\"returns.php\",\"title\":\"Return Policy\"},\"Shipping Policy\":{\"href\":\"stories\\\/515-How-to-Easily-Unload-Power-Equipment.html\",\"title\":\"Shipping Policy\"},\"Product Recalls\":{\"href\":\"stories\\\/1175-Product-Recalls-for-Power-Equipment.html\",\"title\":\"Product Recalls\"},\"Track Order\":{\"href\":\"ordertracking.php\",\"title\":\"Order Tracking\"},\"Accessibility\":{\"href\":\"stories\\\/1769-Our-Commitment-to-Accessibility.html\",\"title\":\"Accessibility\"},\"Do Not Sell or

Share My Personal Information\":{\"href\":\"https:\\\/\\\/ferguson.bigidprivacy.cloud\\\/consumer\\\/#\\\/dMf02ovZbN\\\/Form-NHWperWAaFNVIQK\",\"title\":\"Do Not Sell or Share My Personal Information\"}},\"About Us\":{\"Our Stores\":{\"href\":\"https:\\\/\\\/www.powerequipmentdirect.com\\\/our-stores.php\",\"title\":\"Power Equipment Direct's Stores\"},\"Our Story\":{\"href\":\"https:\\\/\\\/www.powerequipmentdirect.com\\\/stories\\\/1982-How-We-Make-Buying-Technical-Products-Simple.html\",\"title\":\"Power Equipment Direct's Story\"},\"Careers\":{\"href\":\"https:\\\/\\\/www.powerequipmentdirect.com\\\/stories\\\/1924-Job-Openings.html\",\"title\":\"Careers @ Power Equipment Direct\"},\"Newsroom\":{\"href\":\"newsreleases.php\",\"title\":\"Power Equipment Direct News Center\"}},\"Contact Us\":{\"phone\":\"800-710-7499\",\"hours\":[\"M-F: 8-5 CST\",\"Sat: Closed\",\"Sun: Closed\"]}}","storeLinkJSON":"{\"AC Wholesalers\":{\"href\":\"https:\\\/\\\/www.acwholesalers.com\",\"title\":\"AC Wholesalers\"},\"Air Compressors Direct\":{\"href\":\"https:\\\/\\\/www.aircompressorsdirect.com\",\"title\":\"Air Compressors Direct\"},\"eComfort\":{\"href\":\"https:\\\/\\\/www.ecomfort.com\",\"title\":\"eComfort\"},\"Electric Generators Direct\":{\"href\":\"https:\\\/\\\/www.electricgeneratorsdirect.com\",\"title\":\"Electric Generators Direct\"},\"Power Equipment Direct\":{\"href\":\"https:\\\/\\\/www.powerequipmentdirect.com\",\"title\":\"Power Equipment Direct\"},\"Pressure Washers Direct\":{\"href\":\"https:\\\/\\\/www.pressurewashersdirect.com\",\"title\":\"Pressure Washers Direct\"},\"Sump Pumps Direct\":{\"href\":\"https:\\\/\\\/www.sumppumpsdirect.com\",\"title\":\"Sump Pumps Direct\"},\"Water Pumps Direct\":{\"href\":\"https:\\\/\\\/www.waterpumpsdirect.com\",\"title\":\"Water Pumps Direct\"}}","socialLinkJSON":"{\"Facebook\":{\"href\":\"https:\\\/\\\/www.facebook.com\\\/PowerEquipmentDirect\",\"icon\":\"icon-facebook\",\"title\":\"Facebook\"},\"Twitter\":{\"href\":\"http:\\\/\\\/twitter.com\\\/PowerEquipment\",\"icon\":\"icon-twitter\",\"title\":\"Twitter\"},\"Pinterest\":{\"href\":\"http:\\\/\\\/pinterest.com\\\/powerequipment\\\/\",\"icon\":\"icon-pinterest\",\"title\":\"Pinterest\"},\"YouTube\":{\"href\":\"http:\\\/\\\/www.youtube.com\\\/PowerEquipmentDirect\",\"icon\":\"icon-youtube\",\"title\":\"YouTube\"},\"Instagram\":{\"href\":\"https:\\\/\\\/www.instagram.com\\\/powerequipmentdirect\\\/\",\"icon\":\"icon-instagram\",\"title\":\"Instagram\"},\"LinkedIn\":{\"href\":\"https:\\\/\\\/www.linkedin.com\\\/company\\\/power-equipment-direct\\\/about\\\/\",\"icon\":\"icon-linkedin\",\"title\":\"LinkedIn\"}}","miscLinkJSON":"{\"Terms of Use\":{\"href\":\"terms-of-use.php\",\"title\":\"Terms of Use\"},\"Privacy Policy & Security\":{\"href\":\"privacy.php\",\"title\":\"Privacy Policy and Security\"},\"Cookie Policy\":{\"href\":\"privacy.php#cookiePolicy\",\"title\":\"Cookie Policy\"},\"CA Privacy Rights\":{\"href\":\"privacy.php#californiaPrivacyRights\",\"title\":\"CA Privacy Rights\"},\"copyright\":\"© 2024 Power Equipment Direct. All Rights Reserved\"}","checkoutMiscLinkJSON":"{\"Privacy Policy & Security\":{\"href\":\"privacy.php\",\"title\":\"Privacy Policy and Security\"},\"Cookie Policy\":{\"href\":\"privacy.php#cookiePolicy\",\"title\":\"Cookie Policy\"},\"Terms of Use\":{\"href\":\"terms-of-use.php\",\"title\":\"Terms of Use\"},\"copyright\":\"© 2024 Power Equipment Direct. All Rights Reserved\"}","expertJSON":{"imageURL":"https:\/\/www.powerequipmentdirect.com\/images\/experts\/expert-main-13.png","href":"\/product-experts.php?s=13","title":"Contact Dale @ Power Equipment Direct","expertName":"Dale","expertTitle":"Power Equipment Expert"},"bbbJSON":{"imageURL":"https:\/\/www.powerequipmentdirect.com\/images\/badge-bbb.png","imageAlt":"Better Business Bureau\u00ae","href":"http:\/\/www.bbb.org\/chicago\/business-reviews\/industrial-equipment-and-supplies\/power-equipment-direct-in-bolingbrook-il-57001088","title":"Power Equipment Direct - A+ Rating - Better Business Bureau\u00ae"},"zipCode":null,"phoneNumber":"800-710-7499","loginToken":"page cache precludes the use of csrf tokens","iterable":"e4b27e68b9c84fbb940829a0a9ee29d7","newNav":false}

Share My Personal Information\":{\"href\":\"https:\\\/\\\/ferguson.bigidprivacy.cloud\\\/consumer\\\/#\\\/dMf02ovZbN\\\/Form-NHWperWAaFNVIQK\",\"title\":\"Do Not Sell or Share My Personal Information\"}},\"About Us\":{\"Our Stores\":{\"href\":\"https:\\\/\\\/www.powerequipmentdirect.com\\\/our-stores.php\",\"title\":\"Power Equipment Direct's Stores\"},\"Our Story\":{\"href\":\"https:\\\/\\\/www.powerequipmentdirect.com\\\/stories\\\/1982-How-We-Make-Buying-Technical-Products-Simple.html\",\"title\":\"Power Equipment Direct's Story\"},\"Careers\":{\"href\":\"https:\\\/\\\/www.powerequipmentdirect.com\\\/stories\\\/1924-Job-Openings.html\",\"title\":\"Careers @ Power Equipment Direct\"},\"Newsroom\":{\"href\":\"newsreleases.php\",\"title\":\"Power Equipment Direct News Center\"}},\"Contact Us\":{\"phone\":\"800-710-7499\",\"hours\":[\"M-F: 8-5 CST\",\"Sat: Closed\",\"Sun: Closed\"]}}","storeLinkJSON":"{\"AC Wholesalers\":{\"href\":\"https:\\\/\\\/www.acwholesalers.com\",\"title\":\"AC Wholesalers\"},\"Air Compressors Direct\":{\"href\":\"https:\\\/\\\/www.aircompressorsdirect.com\",\"title\":\"Air Compressors Direct\"},\"eComfort\":{\"href\":\"https:\\\/\\\/www.ecomfort.com\",\"title\":\"eComfort\"},\"Electric Generators Direct\":{\"href\":\"https:\\\/\\\/www.electricgeneratorsdirect.com\",\"title\":\"Electric Generators Direct\"},\"Power Equipment Direct\":{\"href\":\"https:\\\/\\\/www.powerequipmentdirect.com\",\"title\":\"Power Equipment Direct\"},\"Pressure Washers Direct\":{\"href\":\"https:\\\/\\\/www.pressurewashersdirect.com\",\"title\":\"Pressure Washers Direct\"},\"Sump Pumps Direct\":{\"href\":\"https:\\\/\\\/www.sumppumpsdirect.com\",\"title\":\"Sump Pumps Direct\"},\"Water Pumps Direct\":{\"href\":\"https:\\\/\\\/www.waterpumpsdirect.com\",\"title\":\"Water Pumps Direct\"}}","socialLinkJSON":"{\"Facebook\":{\"href\":\"https:\\\/\\\/www.facebook.com\\\/PowerEquipmentDirect\",\"icon\":\"icon-facebook\",\"title\":\"Facebook\"},\"Twitter\":{\"href\":\"http:\\\/\\\/twitter.com\\\/PowerEquipment\",\"icon\":\"icon-twitter\",\"title\":\"Twitter\"},\"Pinterest\":{\"href\":\"http:\\\/\\\/pinterest.com\\\/powerequipment\\\/\",\"icon\":\"icon-pinterest\",\"title\":\"Pinterest\"},\"YouTube\":{\"href\":\"http:\\\/\\\/www.youtube.com\\\/PowerEquipmentDirect\",\"icon\":\"icon-youtube\",\"title\":\"YouTube\"},\"Instagram\":{\"href\":\"https:\\\/\\\/www.instagram.com\\\/powerequipmentdirect\\\/\",\"icon\":\"icon-instagram\",\"title\":\"Instagram\"},\"LinkedIn\":{\"href\":\"https:\\\/\\\/www.linkedin.com\\\/company\\\/power-equipment-direct\\\/about\\\/\",\"icon\":\"icon-linkedin\",\"title\":\"LinkedIn\"}}","miscLinkJSON":"{\"Terms of Use\":{\"href\":\"terms-of-use.php\",\"title\":\"Terms of Use\"},\"Privacy Policy & Security\":{\"href\":\"privacy.php\",\"title\":\"Privacy Policy and Security\"},\"Cookie Policy\":{\"href\":\"privacy.php#cookiePolicy\",\"title\":\"Cookie Policy\"},\"CA Privacy Rights\":{\"href\":\"privacy.php#californiaPrivacyRights\",\"title\":\"CA Privacy Rights\"},\"copyright\":\"© 2024 Power Equipment Direct. All Rights Reserved\"}","checkoutMiscLinkJSON":"{\"Privacy Policy & Security\":{\"href\":\"privacy.php\",\"title\":\"Privacy Policy and Security\"},\"Cookie Policy\":{\"href\":\"privacy.php#cookiePolicy\",\"title\":\"Cookie Policy\"},\"Terms of Use\":{\"href\":\"terms-of-use.php\",\"title\":\"Terms of Use\"},\"copyright\":\"© 2024 Power Equipment Direct. All Rights Reserved\"}","expertJSON":{"imageURL":"https:\/\/www.powerequipmentdirect.com\/images\/experts\/expert-main-13.png","href":"\/product-experts.php?s=13","title":"Contact Dale @ Power Equipment Direct","expertName":"Dale","expertTitle":"Power Equipment Expert"},"bbbJSON":{"imageURL":"https:\/\/www.powerequipmentdirect.com\/images\/badge-bbb.png","imageAlt":"Better Business Bureau\u00ae","href":"http:\/\/www.bbb.org\/chicago\/business-reviews\/industrial-equipment-and-supplies\/power-equipment-direct-in-bolingbrook-il-57001088","title":"Power Equipment Direct - A+ Rating - Better Business Bureau\u00ae"},"zipCode":null,"phoneNumber":"800-710-7499","loginToken":"page cache precludes the use of csrf tokens","iterable":"e4b27e68b9c84fbb940829a0a9ee29d7","newNav":false}

We Make Buying Technical Products Simple

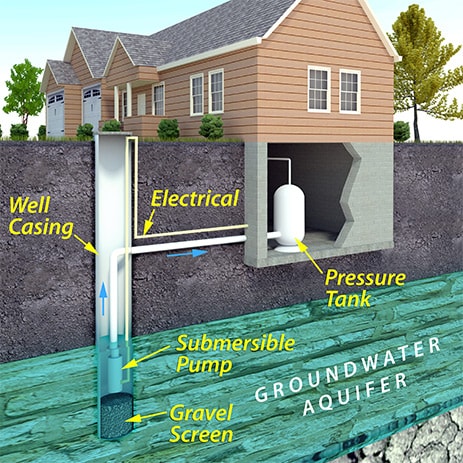

A well pump needs to be primed in order to create the internal pressure necessary to draw water from your well or other water source and pump it to where you need it to go.

A well pump needs to be primed in order to create the internal pressure necessary to draw water from your well or other water source and pump it to where you need it to go. When a

When a

For example, if a check valve or foot valve (pictured right) stops working, water can fall back into the cistern when the pump turns off, resulting in an air pocket created within the pipe. The next time the well pump turns on, it will be sputtering out the air as it struggles to draw water up again. If the motor doesn't burn out first, you will not be able to draw water until it is primed (filled with water) again.

For example, if a check valve or foot valve (pictured right) stops working, water can fall back into the cistern when the pump turns off, resulting in an air pocket created within the pipe. The next time the well pump turns on, it will be sputtering out the air as it struggles to draw water up again. If the motor doesn't burn out first, you will not be able to draw water until it is primed (filled with water) again. A convertible jet pump usually has 2 pipes: one used for water suction, and one for pushing water into a venturi loop, which acts as a siphon by pushing water around the piping loop and up toward your outlet valve. Using water, pressure, and the power of gravity, convertible jet pumps are able to draw water from much deeper wells than shallow-well pumps.

A convertible jet pump usually has 2 pipes: one used for water suction, and one for pushing water into a venturi loop, which acts as a siphon by pushing water around the piping loop and up toward your outlet valve. Using water, pressure, and the power of gravity, convertible jet pumps are able to draw water from much deeper wells than shallow-well pumps. If you've determined that the well pump does not need to be reprimed, and all of the above have been checked, the next thing to do is check the holding (pressure) tank. If your well pump does not have a pressure gauge, it may be useful to have an external pressure gauge installed at the pump or at the outlet to monitor water pressure levels.

If you've determined that the well pump does not need to be reprimed, and all of the above have been checked, the next thing to do is check the holding (pressure) tank. If your well pump does not have a pressure gauge, it may be useful to have an external pressure gauge installed at the pump or at the outlet to monitor water pressure levels.