Air Compressor Filters 101

Without an air line filter - water, oil, and dirt can cause major damage to pneumatic tools, destroy factory equipment, ruin a paint job, and even contaminate food in a production facility.

Proper air treatment is critical to the health of your air system, and compressor filters are an inexpensive investment compared to a costly repair/replacement job.

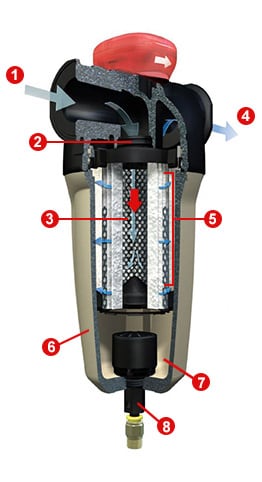

To better understand how these filters work, we will break them down into 8 main components.

1. Air Inlet

As air enters, the internal cap forces it into a downward spiral. Just be sure to size the inlet appropriately for your compressor. You should never use a smaller filter on a larger line.

2. Filter Cap

The filter cap directs the flow of air through the filter. An arrow on the outside of the filter indicates the direction of air flow, and should not be installed backwards.

3. Air Path

In order for the air to be discharged from the filter, it must follow the air path. The air path consists of entering a cyclonic phase and passing through the filter element.

4. Filter Discharge

The filter discharge is the orifice through which the air leaves the filter. The sizing of the discharge should match the inlet size. An under-sized filter will restrict air flow.

5. Filter Element

The filter element is the part that actually filters the air. The filter element catches particulates you wish to remove from the air. As the filter does its job, it becomes clogged with those particulates.

Once the filter is clogged, it will need to be cleaned or replaced. If CFM (cubic feet per minute) decreases, it may be due to a clog in the filter element. Using too fine of a filter element can cause more frequent clogging.

6. Filter Bowl

The filter bowl makes up the largest visible part of the air compressor filter. It connects to the cap housing by either threading into it or twisting and locking into place.

7. Filter Quiet Zone

The filter quiet zone is a zone at the bottom of the filter bowl where contaminants, oil, and water are collected. There is usually a horizontal barrier that hangs down from the bottom of the filter element that prevents debris from becoming re-entrained in the air.

8. Drain

Eventually, the water, oil, and debris in the bottom of the filter bowl must be drained. Some filters come with manual drains, requiring you to periodically remove the plug and drain the contents.

Other filters come with float-operated drains or electric auto drains. Failure to regularly open and drain the collected water and debris will cause the water to rise above the barrier and become re-entrained.

What is a Micron?

Air line filters are measured by the size of the particles they can catch. These particulates are so small they have to be measured in microns (1 micron = one-millionth of a meter). For comparison, a human hair is about 100 microns across and a red blood cell is 8 microns in diameter.

If you are using fine particulate filters, let's say a 5-micron filter, the element inside will trap seemingly invisible particulates smaller than a red blood cell! To avoid immediate clogging of the unimaginably tiny holes in the filter element, it's best to have a general-purpose filter installed upstream to catch larger particulates. Doing so will save you from frequently replacing the small-sized filters, or tossing them altogether!

Air Compressor Buyer's Guide Navigation

Ultimate Compressor Guide |Air Compressors 101| For Homeowners | For Contractors | Stationary Compressors | Portable Compressors| Quiet Compressors | Energy Efficiency | Air Treatment Systems | Air Filters 101 | Air Tools 101 |